Super Side Production

OUR QUALITY & WHY US ?

How do we manufacture Alpha Lathe Machine ? (ग्राहक इसे अवश्य पढ़े और समजे)

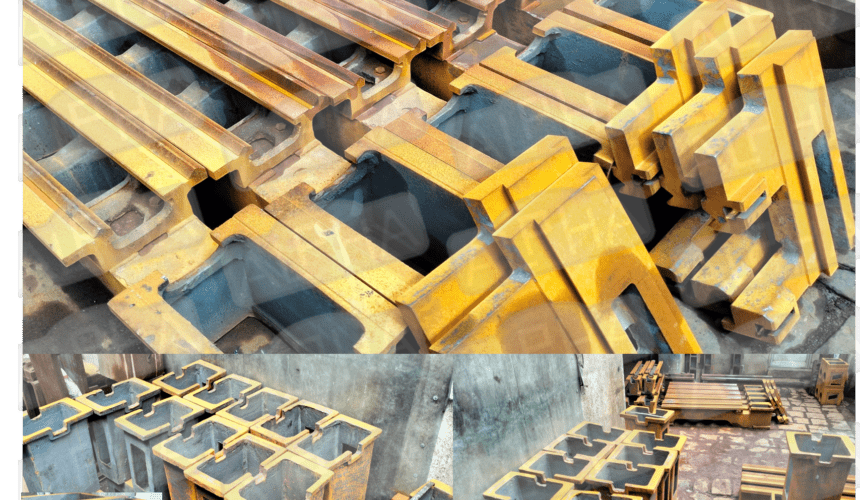

1. CASTING

2. ROUGH MACHINING OF PARTS

3. SEASONING PROCESS OF PARTS

4. BED MACHINING & HARDNING

5. SEASONING PROCESS OF BED

6. GRIDING OF BED (FIRST TIME)

7. SEASONING PROCESS OF BED (SECOND TIME)

8. FINAL GRININD OF BED (SECOND TIME)

9. FINAL MACHINIG OF PARTS

10. SHEET THEORY PROCESS IN 4 PLACES

11. MACHINE LEVELING WITH MICRO LEVEL (Rsk Japan)

12. SHEET THEORY PROCESS IN 20 VARIOUS PLACES

13. MACHINE ASSEMBLY

14. MACHINE TRY & TESTING

15. PAINTING

16. REFITTING

17. FINAL MACHINE TRY & TESTING

18. FINAL INSPECTION LIKE INDIAN STANDARD IS 1878 (PART 1): 1993

19. PACKING

20. DISPATCH

“ALPHA” LATHE MACHINE VS “NORMAL” (ROUTINE) LATHE MACHINE

| SR NO. | “ALPHA” Lathe Machine Specialty | “NORMAL” (ROUTINE) LATHE MACHINE |

|---|---|---|

| (1). | 45 Days Piece To Piece Exchange* (T&C) | Only 30 Days service for Manufacturing Defect |

| (2). | Seasoning Process (Our New Technique) | No Seasoning Process |

| (3). | 24 Place Sheet In The Machine (Our New Technique) | Only 6 To 7 Place Sheet In The Machine |

| (4). | 2 Time Bed Grinding (Our New Technique) | Only One Time Bed Grinding (Urgent) |

| (5). | High Quality Spare Parts | Regular & Cheap Spare Parts |

| (6). | We Use Micro Level To Make The Alpha Lathe Machine (Only Two Leg) | No Level |

| (7). | High Quality And Best Company Bearing | Only Regular Quality & Cheap Or Regular Company Bearing |

| (8). | You Don’t Need To Set Taper From The Headstock In 99% Alpha Lathe Machine* (According to our system you have to leveling the machine with micro level or our other method) | You Need To Set Taper From The Headstock In Normal Lathe Machine |

| (9). | We Balance The Spindle Pulley With Gear, Counter Pulley With Shaft And Aarapully. (Only Our System) | No Balancing |

| (10). | Two Time Try And Testing (Finishing , Small Cut , Big Cut , Fully Machine Testing) | Only One Time Try |

| (11). | Alpha Lathe Machine Is Made With High Precision And Good Inspection | Only once the worker inspects the machine |

| (12). | You will get a higher resale value of the Alpha Lathe Machine (Know it Yourself in the Market) | You will not get higher resale value (Know it Yourself in the Market) |

| (13). | Alpha Lathe(We) build only a limited number of machines so we pay enough attention to each machine | There is no certainty in machine production |

| (14). | 99% Alpha Lathe Machine Ready To Use.(No Any Query) | Normal – Routine Lathe Machine NO Ready To Use.(The taper has to be set !!!) |

| (15). | 32+ Yrs Of Experience & 15000+ Machines Installed |

SEASONING PROCESS THEORY

“ALPHA” LATHE MACHINE VS “NORMAL” (ROUTINE) LATHE MACHINE

| SEASONING PROCESS TYPE | “ALPHA” LATHE MACHINE Specialty – RAJKOT (23/07/2020 TO) | “NORMAL” (ROUTINE) LATHE MACHINE |

|---|---|---|

| (1). Bed Roughing And Hardening | We Keep 15 TO 180 Days for seasoning. (after process 1.) | Doing direct Bed Grinding.(after process 1.) [Bed was complete] |

| (2). Bed Grinding (after Roughing & Hardening & Seasoning) | We Keep 30 Days To 180 Days for seasoning. (after process 2.) | NA |

| (3). Final Finishing And Finishing Grinding Of The Bed after two time seasoning process (after 1. & 2.) | YES [Bed was Complete] | NA |

| (A). Headstock Roughing And Boring | We Keep 15 Days To 120 Days for seasoning. (after process A.) | Doing direct finishing & boring of headstock. (after process 1.) [Headstock was complete] |

| (B). Sheet At The Bottom Of The Headstock And Do The Finishing Boring | YES [Headstock was complete] | NA |

| (I). Sedal, Surface, Compound & Legs Roughing | We Keep 30 Days To 60 Days for seasoning. (after process I.) | Doing direct finishing & boring of sedal,surface & compound. (after process I.) [Parts was complete] |

| (II). Finishing And Boring Of Sedal, Surface And Compound. | YES [Various Parts was complete] | NA |

➢ Why are we doing the seasoning process?

▪ Increases overall machine life

▪ Improves machine accuracy

▪ Micro leveling can be done on machine

▪ Accuracy lasts longer

– We do all seasoning processes as per our company standard (Method).

Quality Maintain SHEET (SCRAPING) THEORY

“ALPHA” LATHE MACHINE VS “NORMAL” (ROUTINE) LATHE MACHINE

| SR NO. | QUALITY MAINTAIN = SHEET THEORY | “ALPHA” LATHE MACHINE – Specialty – (SUPER SIDE PRODUCTION) | “NORMAL” (ROUTINE) LATHE MACHINE |

|---|---|---|---|

| (1). | We Take The Sheet At Bottom Of The Bed (From The Surface Plate) (TWO SHEET) | YES | NO |

| (2). | We Take The Sheet At Above The Face Of The Leg (From The Surface Plate) (two sheets included) | YES | NO |

| (3). | Then We Level The Two Legged Machine With A Horizontal And Vertical Level | YES | NO |

| (4). | WE Take The Sheet Both Between Apron And Sedal. (From The Surface Plate) (two sheets included) | YES | NO |

| (5). | We Take The Sheet At The Sedal Depending On The Bed. | YES | YES |

| (6). | We Take The Sheet At The Bottom Of The Surface. (From The Surface Plate) | YES | NO |

| (7). | We Take The Sheet Between The Sedal And Surface. | YES | YES |

| (8). | We Take The Sheet At The Bottom Of The Compound. (From The Surface Plate) | YES | NO |

| (9). | We Take The Sheet Between The Compound And Surface. | YES | NO |

| (10). | After, We Take The Sheet On Compound Face. (From The Surface Plate) | YES | NO |

| (11). | We Take The Sheet Between Compound Paw And Compound Face. | YES | YES |

| (12). | We Take The Sheet At The Bottom Of The Tool Post.(From The Surface Plate) | YES | NO |

| (13). | We Take The Sheet Between Compound And Toolpost Face. | YES | NO |

| (14). | We Take Sheet At Bottom Of The Headstock. (From The Surface Plate) | YES | NO |

| (15). | We Take The Sheet At The Bed Depending On The Headstock. | YES | YES |

| (16). | We Take The Sheet Counter Breket. (From The Surface Plate) | YES | NO |

| (17). | The Tailstock Patli Depending On The Bed. | YES | YES |

| (18). | Above Tailstock Patli (From The Surface Plate) | YES | NO |

| (19). | Spindle Ring Gear And Kala Sheet (From The Surface Plate) (two sheets included) | YES | NO |

| (20). | “Bottom Of Tailstock (From The Surface Plate) | YES | NO |

-: Total Number Of Sheet :-

“ALPHA” LATHE MACHINE = 24

“NORMAL” LATHE MACHINE = 5 To 8

➢ Why are we doing the sheet theory process?

▪ Reduce machine vibration,

▪ Micro accuracy can be achieved,

▪ Machine running smoothly,

▪ Precision work can be done,

▪ Micro leveling can be done

▪ Precision work can be done,

▪ Micro leveling can be done,

▪ Center to center shaft turning and boring can be done

– We do all sheet theory processes as per our company standard.